BROWSE EQUIPMENT, MATERIALS & SERVICES

available 114 equipment

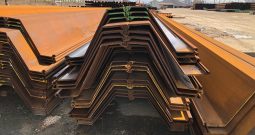

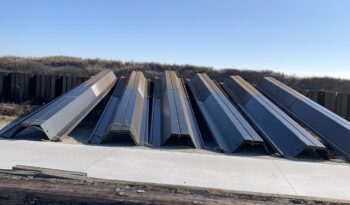

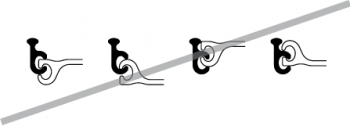

available 84 materials

available 20 services

available 6 listings

available 5 materials

available 0 services

available 198 listings

Search Equipment Inventory

Search Material Inventory

Search Services Inventory

Have Questions? Call Today!

TESTIMONIALS

From pile driving to drilling equipment, we’ve listed and sold multiple pieces of equipment with Steel Giant and will continue to use them as a vendor in the future!

We find that listing with the Steel Giant, not only takes the least amount of effort but has also proven to be the quickest way to sell our used equipment and materials.

We’ve worked with Greg and the Steel Giant team on several occasions, specifically regarding purchasing and selling used steel sheet pile.