Steel sheet piling is heavily relied on in construction for holding back large quantities of soil and water. Yet, while widely used, it’s often misunderstood – especially when it comes to comprehending its uses. This article will explain more about this material and the many benefits it offers.

What’s Steel Sheet Piling?

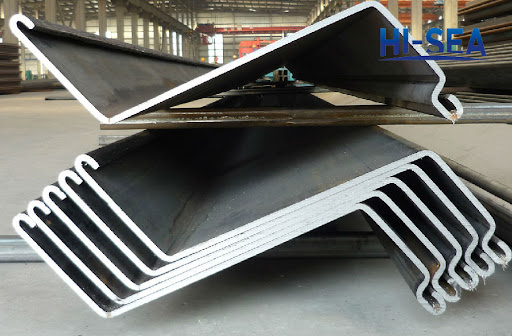

This material is composed of thick steel pieces with interlocks. When situated together, the interlocks will slip in place to create a sturdy barrier. As it’s pushed into the soil, the pressure created will shove against the earth helping to keep the terrain even and contained.

Thanks to its versatility, steel sheet piling comes in various thicknesses. You’ll want to check different aspects of them to ensure the piece fits your needs. Some details to investigate include the:

- Flange

- Web

- Pile weight

- Area

Benefits of Steel Sheet Piles

This material comes with a handful of impressive perks. Some of these include:

- Being stress-resistant.

- Having a long lifespan.

- Being versatile (it can be used both on land and in the water).

- Featuring strong interlocks.

Are There Downsides to Steel Piles?

Steel sheet piles offer more pros than cons, but there are still a few things to be aware of. One is that this material doesn’t work well on rocky terrains. Besides this, it could cause intense vibrations when being installed.

How It’s Made

You’ll notice that steel sheet piling will either be hot-rolled or cold-pressed.

Hot-Rolled

This is one of the most commonly used processes when making steel sheet piles. A billet (a long steel beam) will be pushed into an extremely hot (usually around 1,700℉) machine. The temperature will slowly melt the billet so that it can be pressed into a thin sheet. As it travels through the machine, thick rollers will ensure the sheet stays even and free from blemishes. It will then leave the machine and be left to cool.

Hot-rolled steel sheet piles are a bit sturdier than cold-pressed ones thanks to their thick locks. They also tend to be more waterproof.

Cold-Pressed

Cold-pressed steel piles only hit the market in the 1970s, but they have quickly gained traction. With this option, a billet will also be heated, but in the middle of the process, the piece will be left to cool. It will then be pushed through the machine once more, heated, and then shaped.

Cold-pressed steel sheet piles tend to be less expensive. They’re also a bit more flexible.

Steel Sheet Pile Shapes

Larssen

This design features deep troughs with multiple locks along the neutral axis. Each piece will close together at a 180° angle. Because of its unique layout, larssen shaped steel sheet piles are often used for retaining walls and cofferdams.

Z

Z-shaped sheet piles look similar to larssen ones, but their locks are instead placed on the outer edge. You’ll notice that they come in different angles, so the interlocks will connect together in various ways.

Straight Web

As its name suggests, a straight web sheet pile is formed in a flat vertical shape. It features thin locks on the top edges where other straight web pieces can slide into. Straight web piles are ideal for projects where anchoring or certain excavation depths are difficult.

How Steel Sheet Piles are Installed

Perhaps one of the most unique aspects of steel sheet piles is their installation. Because of this material’s rigidity, it requires strong equipment and methods to insert it. Some of the most frequently used are hydraulic pushing, vibrating/impaction, trenching, and jetting.

Hydraulic Pushing

This method uses a hydraulic clamp to press the steel sheet into the ground. Thanks to this process, it eliminates noise and vibrations making it a popular method to use in urban areas.

Hydraulic pushers come in a variety of styles. It’s critical to look at these dimensions to make certain they meet the steel sheet pile’s needs. In some cases, a hydraulic pusher will add counterweights to assist with propelling the sheet pile into the ground faster.

Vibrating/Impaction

Vibrating and impaction methods rely on vibrating hammers to lower steel sheet piles into the landscape. With the help of clamps, a hammer will grab the sheet pile’s top edge and produce vertical pressure to send it into the soil. This feature also prevents the steel piece from bending or warping as it’s inserted.

Trenching

If you plan to use the steel sheet piles in excavations, this process is probably ideal. Trenching requires trenches to be made in the ground. Once they are, the steel piles can be slid into place within them.

Jetting

Jetting uses small water jets to moisten the ground as the pile driver goes in. Similar to hydraulic pushing, this process also helps break down hard dirt clumps which would otherwise make it difficult to secure the pile.

Is Aluminum Sheet Piling the Same as Steel?

While this material has many similarities, there are stark differences. Steel is heavier, but it’s more solid. This prevents it from warping – a common problem with aluminum piles. On the other hand, aluminum isn’t as susceptible to corrosion making it ideal to use in marine construction.

Recycled Steel Piles – Are they Safe?

As more companies are becoming eco-focused, you might come across recycled steel sheet piles. While some might be hesitant to use old materials, they’re still reliable. They undergo numerous tests to certify they’re durable. If they don’t pass, they’re melted down and repurposed.

Where Can I Find Steel Sheet Piling?

Steel piles can usually be found at local construction supply sites. However, the options available will vary depending on the company’s stock. Some might not have what you’re looking for and may need to make a customized order.

You can also do a quick online search. This can guide you toward steel sheet pile manufacturers in your area. You can also get a better idea of their inventory by doing so.

Steel sheet piling is perfect for tough projects that require sturdy support. By using this information, you can easily determine whether steel sheet piles are the right material for your needs.