Load bearing piles are designed to hold soil layers over a vertical structure to keep it stable. But, because of its intricacies, it’s important to understand the different types available and the science behind them. Below you’ll find more about countless load bearing pile materials and the various ways they can be applied.

Load Bearing Pile Types

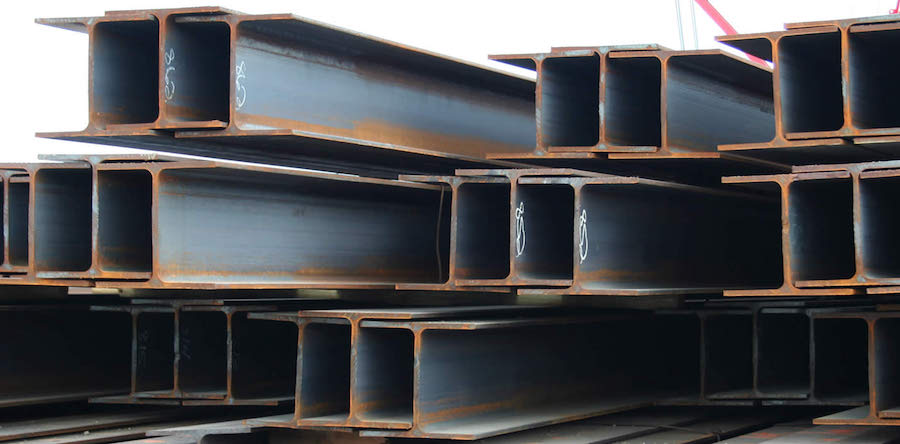

Steel

This material is one of the strongest making it the preferred option for most construction projects. It can hold high amounts of stress and is often used to create H-piles. A steel H-pile works well with end-bearing piles and is typically used to construct highway bridge piers.

One of the biggest perks of steel piles is that they come in numerous sizes. They’re also widely available. However, this alloy is susceptible to corrosion and doesn’t always provide the best friction.

Steel piles will either be hot or cold-pressed. A hot-pressed one is heated at staggering temperatures making it flimsy enough to bend and mold. A cold-pressed pile follows this same process but is cooled and then re-rolled. This makes it a bit harder and able to resist extra tension.

Timber

Timber load bearing piles are cut from pine and fir trees and later carved and pressed into thick rounded boards. While some pieces aren’t treated, most timber piles are chemically preserved to ensure they stay durable.

This selection is budget-friendly, provides great tension, and is simple to install. However, they only have a small bearing capacity and can splinter with hard driving.

Composite

Composite load bearing piles are composed of plastic and recycled materials. While not as strong as pure steel, composite load bearing piles are powerful and can often be drilled into rocks. Sometimes, they will even be used to coat steel load bearings to provide extra support.

Composite selections are affordable but it can sometimes be difficult for the material to have a good joint.

Concrete

This option is heavily relied on to keep a structure anchored in poor soil conditions. Concrete selections also support lateral loads that could be stressed.

Concrete load bearings come in two types: pre-cast and cast-in-situ.

Pre-Cast

A pre-cast concrete load bearing pile provides additional strength to the material because it stays in a rigid shape. While it can be formed into different designs, once it’s set, it stays firm in that position. Thanks to its distinctive composition, pre-cast concrete piles are safe to use in marine construction.

Cast-in-Situ

This option will either be cased or uncased. A cased cast-in-situ is when a steel case is drilled into the ground and later filled with concrete. An uncased cast-in-situ uses the same process but its casing will slowly be removed after the concrete is set. This selection is easy to install and is adaptable.

What are H-Piles?

H-piles are one of the most frequently used load bearing pile designs. As their name suggests, they resemble an “H”. Set between two horizontal steel beams is a thin vertical one. This design allows them to stay stable and hold a large amount of stress. Due to this, they are often necessary for building structural foundations.

H-piles can be used as end-bearing, friction, and soldier beams.

End-Bearing

An end-bearing H-pile is typically drilled into rocks. Because the boulder itself often has intense strength, it will create an impressive sturdiness when combined with an end-bearing H-pile.

Friction

Friction H-piles are used in sand as they need to be drilled deep into the terrain to stay firm. Unlike some other load bearing piles, friction ones move up and down as they’re inserted into a landscape.

Soldier

Soldier H-piles are used to secure vertical piles by composing a retaining wall around them. Most will be made of timber or concrete to prevent lagging and can be formed into cross-bracing patterns to provide further support.

Closed vs. Open-Ended Piles

As you research load bearing piles you’ll find that they can be either closed or open-ended.

Closed-Ended Piles

This option is shaped into various designs, such as H-piles, and is hollow before potentially being filled with concrete. Depending on the conditions, the pile might need to be closed with a plate.

Open-Ended Piles

This type is counted on when hard driving must be done at the site. To prevent the pile from being damaged, open-ended piles are equipped with a unique shoe that makes certain it keeps its form as it’s being pushed into the ground. Often, it’s used where there are horizontal loads because it keeps this angle in place, especially if it’s susceptible to bending.

Are There Other Types of Piles?

While the ones mentioned above are the most frequently used, there are a few other options available.

Monotube

This selection uses cold-pressed steel beams with cross-sections to keep it steady. It’s usually fitted with a shell which is later filled with concrete.

Raymond Step-Taper

This option uses a tapered steel shell that’s embedded into the ground with the aid of a mandrel. Concrete is then poured into its outer shell. Raymond step-taper piles are versatile but the shells aren’t always the most durable.

Drilled-In Caissons

For those who need a load bearing pile in a deep foundation, drilled-in caissons are ideal. With the help of a caisson, the pile is plunged into the ground and immersed with concrete. It has a high-load capacity but the process needs to be done carefully. Otherwise, you risk accidentally damaging the pile.

How Load Bearing Piles are Inserted

While the pile will be embedded into the ground in various ways, most tend to follow the same process.

The first thing to do is dig a hole big enough to hold it. This should be slightly larger than the pile but must match its exact length.

Once this is done, slide a pre-cast or cast-in-situ shell into the opening. After it’s secure, fill it with concrete and give it time to dry.

Load bearing piles are critical construction components but ones that need to be carefully understood. By using this information, you can determine the right type and style that your project needs.